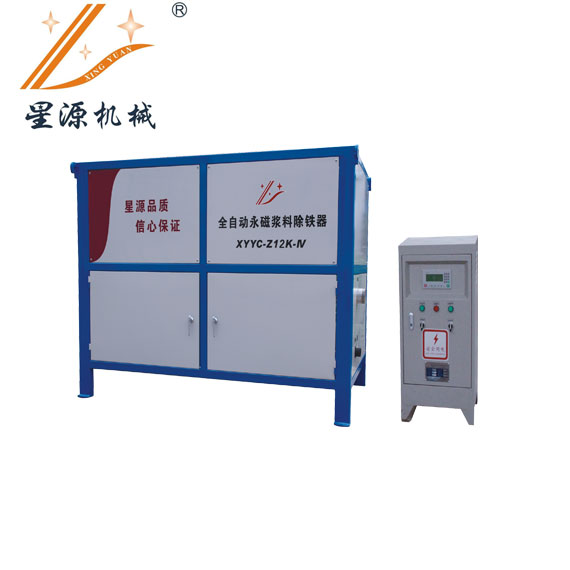

XYYC-Z12K-IV

Wet permanent magnetic separator type automatic type

(Application):

This wet permanent magnetic separator is come out to solve the problem of small magnetism contamination, difficulty of iron removal, high failure. This new magnetic separator has function of lower consumption, lower water consumption, good separation effect, automatic iron remove, working time adjustable, lower failure, big production capacity. It is now widely used in mining, non-metallic minerals, ceramic and electronic industry magnetic separation in slurry or liquid form.

(features):

l High gradient magnetic field: the high magnetic field is up to 12000GS by using the good magnetic medium ,this machine can remove over 95% of the ferromagnetic materials in over 200 mesh particle separation.

l Big in capacity: this machine can produce over 30 ton per hour in slurry form .

l Low energy consumption: this machine consumes 0.1KW per hour ,water usage is lower than 0.2m3 per hour.

l Countercurrent type is used for remove iron, we adopt return flow pipe to make best of raw material.

l Longer lifetime: use high performance permanent grate, the annual demagnetization rate is less than 0.05%.

l The visible control panel is employed here , the time for removal process is adjustable.

(Parameters):

Model |

Rated voltage |

Rated power |

Background Magnetic field |

Processing capacity |

Dimensions |

Weight |

XYYC-Z12K-IV | 380V | 1.5KW | 7000GS | 25-30T/H | 2150*1200*1750 | 1000KG |

Note: there are differences in processing capacity between ore pulp and dry ore, the following indicators are for reference only, to be confirmed in accordance with the actual materials.

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Permanent magnet slurry magnetic separator series

Permanent magnet slurry magnetic separator series

Dry electromagnetic separator automatic type

Dry electromagnetic separator automatic type

Automatic permanent magnet iron remover series

Automatic permanent magnet iron remover series

Magnetic products

Magnetic products

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Permanent magnet belt iron remover

Permanent magnet belt iron remover

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

Vertical ring high gradient magnetic separator series

Vertical ring high gradient magnetic separator series

Automatic powder permanent magnet iron remover series

Automatic powder permanent magnet iron remover series

Permanent magnet belt iron remover series

Permanent magnet belt iron remover series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Automatic slurry permanent magnet iron remover series

Automatic slurry permanent magnet iron remover series

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

Vertical ring high gradient magnetic separator series

Vertical ring high gradient magnetic separator series

Permanent magnet belt iron remover series

Permanent magnet belt iron remover series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Drawer type permanent magnet eliminator series

Drawer type permanent magnet eliminator series

Vertical ring high gradient magnetic separator series

Vertical ring high gradient magnetic separator series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Permanent magnet rotating dry powder automatic iron remover

Permanent magnet rotating dry powder automatic iron remover

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Pipe type permanent magnet iron removal series

Pipe type permanent magnet iron removal series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Dry permanent magnet roller belt type iron remover series

Dry permanent magnet roller belt type iron remover series

Permanent magnet drum type magnetic separator

Permanent magnet drum type magnetic separator

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

Stainless steel roller screen series

Stainless steel roller screen series

High magnetic water processor

High magnetic water processor

Permanent magnet belt iron remover series

Permanent magnet belt iron remover series

Suspended rare earth permanent magnet iron remover

Suspended rare earth permanent magnet iron remover

Rare earth permanent magnet chute plate iron remover

Rare earth permanent magnet chute plate iron remover

Rare earth permanent magnet pipe type iron remover

Rare earth permanent magnet pipe type iron remover

Dilute earth permanent magnet grid rotary iron remover

Dilute earth permanent magnet grid rotary iron remover

Rare earth permanent magnet grid type iron remover

Rare earth permanent magnet grid type iron remover

Rare earth permanent magnet high gradient magnetic filter

Rare earth permanent magnet high gradient magnetic filter

Drawer type iron remover with rare earth permanent magnetic

Drawer type iron remover with rare earth permanent magnetic

Rare earth permanent magnetic bar and bar type iron remover

Rare earth permanent magnetic bar and bar type iron remover