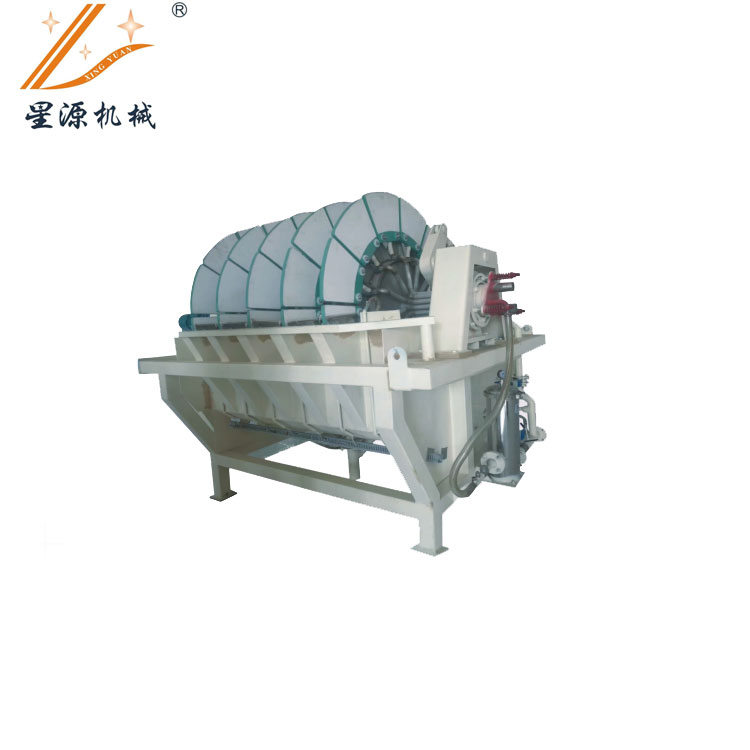

Ceramic Filter

(Application)

Ceramic filter is a new type of high efficiency and energy saving solid-liquid separation equipment.At present, the product has been widely used in the filtration of iron concentrate,copper concentrate,lead concentrate,aluminum concentrate ,nickel concentrate,gold concentrate,phosphorus concentrate,fluorite concentrate and other mining industry at home and aboard.

(Features)

·High vacuum,good drying performance,high productivity efficiency,high solid recovery;

·Filtrate is clear and transparent ,so that working environment is clean and pollution-free;

·PLC control,high level of automation,easy to operate,stable and reliable operation;

·Continuous operation,high utilization rate;

·Remarkable energy saving effect,low operation cost,no need of expensive filter cloth,less spare parts consumption,energy saving about 90% compared with the traditional filter equipment;

·Excellent performance,compact structure,low installation cost ,convenient maintenance.

Similarities&Differences between Ceramic filter and Disc vacuum filter:

The principle between Ceramic filter and Dis vacuum filter is similar:Under the action of pressure difference,when the suspension passes through the filtration medium,the particles are trapped on the surface of the medium to form filter cake,while the liquid flows out through the filtration medium,which to achieve the purpose of solid-liquid separation.

The differences is that the filter medium(ceramic filter plate) has produced the porous capillary effect,make the pores of capillary force is grater than force imposed by the vacuum,keep the micro porous always full of liquid state;no matter under what circumstances,ceramic filter plate does not allow through the air,because there is no air through,solid-liquid separation with low energy consumption and high vacuum level,ceramic filter is mainly composed of rotor,stirring mixing device,blade,slurry tank,distributor,ceramic filter plate,vacuum system,cleaning system and automatic control system etc....

(Technical parameters)

Model | Filter Plate (Round) | Filter Plate (PCS/Model) | Volume of Tank(m³) | Running Power (KW) | Dimensions (L*W*H)(m) |

XY-20 | 4 | 48 (NO.5 Plate) | 4 | 9 | 3.1*3.0*2.99 |

XY-25 | 5 | 60 (NO.5 Plate) | 4.5 | 10.5 | 3.4*3.0*2.99 |

XY-30 | 6 | 72 (NO.5 Plate) | 5 | 11 | 3.7*3.0*2.99 |

XY-35 | 7 | 84 (NO.5 Plate) | 6.5 | 16 | 4.0*3.0*2.99 |

XY-45 | 9 | 108 (NO.5 Plate) | 7.5 | 17 | 4.6*3.0*2.99 |

XY-60 | 12 | 144 (NO.5 Plate) | 9 | 21 | 6.5*3.0*2.99 |

XY-80 | 16 | 192 (NO.5 Plate) | 14.5 | 24 | 8.0*3.0*2.99 |

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Permanent magnet slurry magnetic separator series

Permanent magnet slurry magnetic separator series

Dry electromagnetic separator automatic type

Dry electromagnetic separator automatic type

Automatic permanent magnet iron remover series

Automatic permanent magnet iron remover series

Magnetic products

Magnetic products

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Permanent magnet belt iron remover

Permanent magnet belt iron remover

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

Vertical ring high gradient magnetic separator series

Vertical ring high gradient magnetic separator series

Automatic powder permanent magnet iron remover series

Automatic powder permanent magnet iron remover series

Permanent magnet belt iron remover series

Permanent magnet belt iron remover series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Automatic slurry permanent magnet iron remover series

Automatic slurry permanent magnet iron remover series

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

Vertical ring high gradient magnetic separator series

Vertical ring high gradient magnetic separator series

Permanent magnet belt iron remover series

Permanent magnet belt iron remover series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Drawer type permanent magnet eliminator series

Drawer type permanent magnet eliminator series

Vertical ring high gradient magnetic separator series

Vertical ring high gradient magnetic separator series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Permanent magnet rotating dry powder automatic iron remover

Permanent magnet rotating dry powder automatic iron remover

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Pipe type permanent magnet iron removal series

Pipe type permanent magnet iron removal series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Dry permanent magnet roller belt type iron remover series

Dry permanent magnet roller belt type iron remover series

Permanent magnet drum type magnetic separator

Permanent magnet drum type magnetic separator

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

Stainless steel roller screen series

Stainless steel roller screen series

High magnetic water processor

High magnetic water processor

Permanent magnet belt iron remover series

Permanent magnet belt iron remover series

Suspended rare earth permanent magnet iron remover

Suspended rare earth permanent magnet iron remover

Rare earth permanent magnet chute plate iron remover

Rare earth permanent magnet chute plate iron remover

Rare earth permanent magnet pipe type iron remover

Rare earth permanent magnet pipe type iron remover

Dilute earth permanent magnet grid rotary iron remover

Dilute earth permanent magnet grid rotary iron remover

Rare earth permanent magnet grid type iron remover

Rare earth permanent magnet grid type iron remover

Rare earth permanent magnet high gradient magnetic filter

Rare earth permanent magnet high gradient magnetic filter

Drawer type iron remover with rare earth permanent magnetic

Drawer type iron remover with rare earth permanent magnetic

Rare earth permanent magnetic bar and bar type iron remover

Rare earth permanent magnetic bar and bar type iron remover